News

60-80 Tons Per Day Philippines Full Set Rice Mill Line/Automatic Rice Mill Machine

Release time:

2019-08-06

60-80 Tons Per Day Philippines Full Set Rice Mill Line/Automatic Rice Mill Machine

Specification

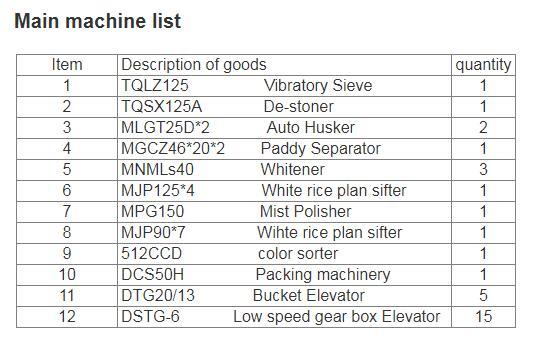

60-80/day complete set rice mill machinery from claner ,de-stoner ,husker ,

whtiner .grader .mist polisher to color sorter ,packing machinery .input

capcity will be 5-6 tons per hour ,out put will be 3-4 tons per hour.

The rice milling complete equipment comprises scalping machine of quality

properties, cleaning sieve, stoner, rubber roller rice huller, grain sieve,

grit, iron roller whitening machine, rice sizing screen, rice polishing

machine and high efficient bucket elevator and electric control panel etc.

The whole process from grain classifying, rice hulling and husked rice

separating, rice milling to rice classifying is all computerized.

Details

1. TQLZ100 Vibratory sieve can remove large, middle, small and light

impurties from grain simultaneously; Plane rotary movement has higher

efficiency; Smooth operation and long service life; Multiple sizes and

specifications to meet different requirements; Suitable for assorted

grain such as rice, wheat, maize and bean etc.

2. TQSX100 de-stoner separetor stones and heavy impurties from rice

utilizing bulk density difference. It is mainly used to separete the

heavy impurties such as stone, mud and etc from rice, wheat, and

other grains. Based on different gravities between grains ans grain-sized

stones.

3. MLGT25D*2 Husker adopting a new vibratory feeding system. Stepleess

adjustment could be done to the vibration frequency according to actual

production. Feeding looks like waterfall, big and uniform. Backed up

shedding plate automatic tracking rubber roll devices to ensure

feeding

accuracy,making operation of rubber roll optimal.

4. MGCZ46*20*2 paddy separator is suitable for the grading and separation

of brown rice and milled rice high efficiency, durable, stable operation,

low maintenance requirements, lower energy consumption.

5. MNMF25 Whitener, new structure, good mechanical stability and easy

disassembly. Higher pressure of suction for milling so as to make brokens less,

rice higher quality and bran fewer. Feeder device micro-adjusted guarantees

rice flow enter into milling chamber stably and evenly. Due to adopt

feeding with tangent and direction-followed model, the machine can

acquire maximum capacity.

6. MJP100*4 Rice plan sifter can shift milled rice efficiently and

accurately into several classes: head rice, large broken, medium broken,

samll broken and etc.

7. MPG150 Mist polisher is used for fine processing of rice. By processing,

it can effectively remove the bran powders in the rice, improve the

oxidation resistance capacities of rice, make the processed rice clean

and fresh and

extend the length for presservation, after which the processed rice can be

eaten as washed rice.

8. A5 CCD color sorter, could completely resolve the rejection difficulties

of those different color granules, mildewed granules and faint yellow sopy

of rice, improve quality and guarantee foods security thereby.

Features

It features characteristics as follows:

1. Each major operation machines are driven by independent electric motor

assorted by electric control panel for separate controls.

2. The techniques can be specially designed and flexibly assembled in

accordance with what is required by users that can process rice of various

precision.

3. Paintings can use static injection techniques that show bright and

clean facade and lasting lustre.

4. The pipe for materials adopts glass pipe that is both artistic

and durable.

5. The dust extraction adopts high-efficient dust collecting units that

satisfy the requirements fo environmental protection.

Previous page

Next page

Previous page

Next page

Related news

PRODUCT SEARCH

Rice destoner Rice husker Paddy separator Rice whitener Rice grader Rice cleaner Rice polisher

Contact

Address:Intersection of Longgang and Xinyi Road, Economic Development Zone, Yunmeng County, Xiaogan City, Hubei Province

Quick navigation

Messages